Inside the Process: Crafting Pre-Rolls at Dispensaries

In the ever-evolving landscape of cannabis culture, pre-rolls have emerged as a popular choice for both seasoned enthusiasts and curious newcomers. These convenient little bundles of joy offer a straightforward way to enjoy the benefits of marijuana without the hassle of rolling one’s own. But what goes on behind the scenes in dispensaries as they prepare these neatly packed wonders? From selecting the finest quality flower to mastering the art of rolling, the process of crafting pre-rolls is both meticulous and interesting. join us as we peel back the layers of this intricate procedure,exploring the techniques,tools,and expertise that transform raw cannabis into delightful pre-rolled products ready for consumers to enjoy. In the following sections, we will uncover the craftsmanship, the science, and the passion that breathe life into these popular offerings, revealing why they are more than just a convenient option but a testament to the artistry within the cannabis industry.

Understanding the Basics of Pre-Roll Production

Pre-roll production begins with the careful selection of cannabis strains, ensuring that the chosen materials align with the desired flavor, potency, and effect. Dispensaries often curate a variety of strains,considering factors such as THC and CBD levels,terpene profiles,and consumer preferences. Quality control is paramount during this stage, as only the best flower will be transformed into pre-rolls, maximizing both customer satisfaction and experience.

After selecting the appropriate strains, the next phase involves grinding and sifting the cannabis. This process not only creates a uniform consistency, which is vital for even burning, but it also helps eliminate stems and seeds that could mar the smoking experience. The ground flower is then tested to ensure it meets the specific standards set forth by the dispensary, maintaining a consistent product that consumers can trust.A meticulous approach during this stage can significantly impact the overall quality of the final product.

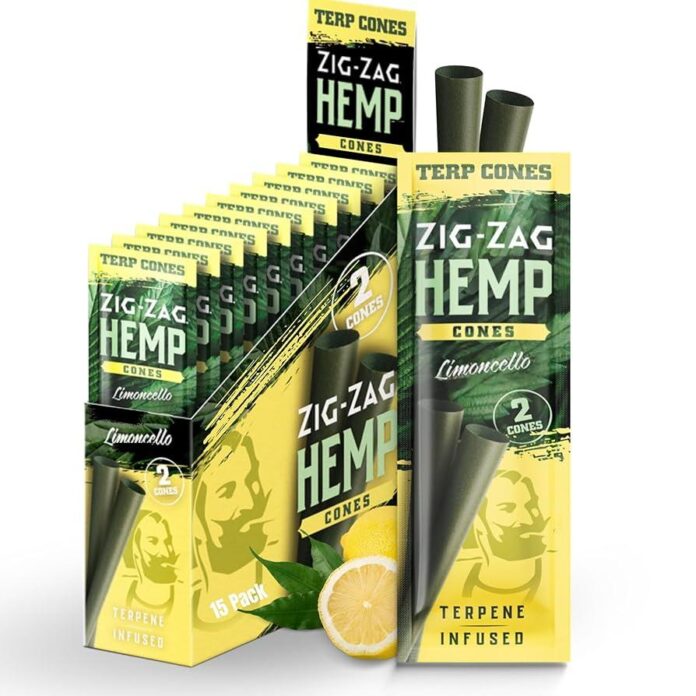

Once the flower is prepared, it’s time for rolling and packaging. Skilled staff members utilize specialized machines or hand-roll each cone, depending on the dispensary’s practices. Attention to detail is critical; well-rolled pre-rolls should feel firm yet not overly packed, allowing for optimal airflow. After rolling, the pre-rolls are typically packaged in child-resistant tubes or boxes. Below is a simple overview of the essential steps in pre-roll production:

| Step | Description |

|---|---|

| Strain Selection | Choosing the right cannabis strains for desired effects. |

| Grinding | grinding flower for consistency and eliminating unwanted materials. |

| Rolling | Rolling techniques ensure a high-quality smoking experience. |

| Packaging | Using secure, stylish containers to maintain freshness. |

Choosing the Right Strains for Optimal Flavor and Effect

Choosing the ideal cannabis strains for pre-rolls involves a careful balance of flavor, aroma, and desired effects. Each strain boasts unique terpenes and cannabinoids, contributing to a distinct sensory experience. dispensaries typically analyse various attributes, such as flavor profiles and potency levels, to ensure they meet consumer preferences. Hear are some key considerations:

- Flavor Profiles: Different strains have varying flavors ranging from earthy to fruity. Some popular categories include:

- Citrus: Bright and refreshing with notes of lemon or orange

- Spicy: Earthy flavors reminiscent of pepper or clove

- Sweet: Dessert-like profiles featuring hints of vanilla or berry

- Aroma: The scent of the strain can enhance the overall experience and is frequently enough just as meaningful as the flavor. Strains are selected based on their pungency and aromatic complexity.

- Effects: understanding the effects associated with different strains-such as relaxing, energizing, or euphoric-allows dispensaries to guide customers toward their ideal choice.

To streamline the selection process, dispensaries usually categorize strains based on their dominant effects and flavors. Below is a simplified table showcasing some recommended strains for pre-rolls, highlighting their primary characteristics:

| Strain Name | Flavor Profile | Primary Effect |

|---|---|---|

| Blue Dream | Fruity, Sweet | Euphoric, Relaxing |

| Trainwreck | Earthy, Spicy | Creative, Uplifting |

| GSC (Girl Scout Cookies) | Sweet, Minty | Happy, Relaxed |

| OG Kush | Pine, Earthy | Calming, Stress-relieving |

Ultimately, the process of selecting the right strains for pre-rolls is not only about understanding flavor and effect, but also about creating a personalized experience for consumers. By focusing on superior quality and offering diverse options, dispensaries can cater to various tastes and needs, ensuring each pre-roll delivers an enjoyable smoking experience. Educating customers on these factors helps cultivate a more informed and satisfied clientele.

The Importance of Quality control in Pre-Roll Crafting

Quality control plays a critical role in the pre-roll crafting process, ensuring that each joint meets the high standards expected by consumers. The artistry of pre-rolls goes beyond just rolling techniques; it demands precision, consistency, and safety. By implementing strict quality control measures, dispensaries can achieve a balanced product that delivers a smooth smoking experience and potency that consumers trust.

A meticulous quality control process typically involves the following steps:

- Material Inspection: checking the quality and freshness of cannabis flower and additional ingredients before they are blended.

- Weight Verification: Ensuring that each pre-roll contains the correct amount of product to provide a consistent experience.

- Rolling Consistency: Examining the technique used in rolling to avoid any loose or overly packed joints, which can affect burn quality.

- Final Product Testing: Conducting tests like lab analyses to check for potency, pesticide residue, and contaminants.

The outcome of these quality control measures can be viewed in a structured format within the dispensary’s operations. Here’s how quality control translates into product excellence:

| Factor | outcome |

|---|---|

| High-Quality Materials | Consistent flavor and effects. |

| Standardized Weights | Reliable dosing for users. |

| Expert Craftsmanship | Improved burn rate and smoking experience. |

| Rigorous Testing | Enhanced safety and consumer confidence. |

Innovative Techniques for Consistent Rolling

To achieve flawless consistency in pre-rolls, dispensaries are embracing cutting-edge methods to refine their rolling techniques.One prevalent approach is the use of precision grinders,which produce a uniform grind size essential for achieving an even burn.by employing electronic grinders with adjustable settings, budtenders can ensure that each batch of flower is ground to the perfect texture, thus enhancing the overall experience for customers.

Moreover, the role of mechanized rolling machines cannot be understated. These devices, designed to accommodate various sizes and shapes of papers, have revolutionized the process by providing speed and uniformity that hand-rolling simply cannot match. Many dispensaries are investing in these machines, which not only streamline production but also minimize the human error that can lead to inconsistent rolls. By automating routine tasks, dispensaries can focus on quality control and fine-tuning their product offerings.

Lastly, quality control protocols play a critical role in maintaining consistency. Implementing a multi-step inspection process ensures that every pre-roll meets specific standards before it reaches the customer.This might include visual checks for weight accuracy and uniformity, as well as smoking tests for burn quality and flavor profile. Dispensaries frequently enough document these inspections to adjust techniques and improve future batches:

| Inspection Stage | Description |

|---|---|

| Weight Check | Ensures each pre-roll meets the specified weight. |

| Visual Inspection | looks for uniformity in size and density. |

| Test Smoke | Assesses burn rate and flavor profile. |

Packaging and Presentation: Elevating the Customer experience

In the world of cannabis, the journey from seed to sale involves much more than just the product itself; it’s also about how that product is presented. The packaging of pre-rolls plays a significant role in not only protecting the product but also in capturing the essence of the brand. Creative designs can make a strong initial impact, ensuring that each customer feels a sense of excitement and anticipation the moment they lay eyes on the product. Every characteristic, from the texture of the packaging to the use of color schemes, communicates a message about quality and care.

Details matter when it comes to elevating customer satisfaction. Engaging packaging often includes features such as:

- Eco-friendly materials that resonate with environmentally conscious consumers.

- Clear labeling that includes strain information, potency, and flavor profiles to inform and delight customers.

- Unique shapes or structures that set the product apart from competitors on the shelf.

In many cases, packaging also doubles as a storytelling medium, reflecting the brand’s values and ethos. Customers are drawn to pre-rolls that encapsulate a lifestyle or a promise, enhancing their overall experience. Providing a memorable unboxing experience can lead to deeper connections between brands and consumers, fostering loyalty and encouraging repeat purchases.

| Feature | Benefit |

|---|---|

| Child-resistant packaging | Ensures safety and complies with regulations |

| Windowed designs | Allows customers to see product quality at a glance |

| Customizable packaging | Enhances brand identity and consumer recall |

Education and Transparency: Building Trust with Consumers

Consumers today are more informed than ever, and when it comes to cannabis products, they expect a high level of education and transparency from their dispensaries. This expectation fosters trust, encouraging customers to engage with brands that prioritize open communication about their products. dispensaries can build this trust by providing detailed information about the sourcing of their cannabis, the manufacturing processes of their pre-rolls, and the quality assurance measures they implement. Importantly, sharing knowledge about strain genetics and cannabinoid profiles can demystify the product for consumers, making them feel empowered to make informed choices.

Effective transparency also includes clear labeling and product testing results. Many consumers want assurance regarding the safety and potency of the products they purchase.Dispensaries should consider implementing educational signage and labels that provide thorough details, such as:

- Strain Type: Indica, Sativa, or Hybrid

- THC/CBD Content: Exact percentages to inform dosing

- Testing Information: Third-party lab results, including contaminants testing

Creating an atmosphere of openness extends beyond product presentation-it also includes consumer engagement. Implementing workshops or Q&A sessions where customers can learn about the roll-making process and the difference between various strains and methods can greatly enhance the experience.For example, consider a table that outlines:

| Strain Name | effects | Best For |

|---|---|---|

| Blue Dream | Euphoric, Relaxing | Stress, Pain Relief |

| OG Kush | Uplifting, Happy | Anxiety, Depression |

| Girl Scout Cookies | Creative, Hungry | Appetite loss, Insomnia |

This initiative not only delivers valuable knowledge but also allows dispensaries to connect more deeply with their customer base. When consumers feel included in the educational journey and have access to the information they crave,they are more likely to return and become loyal patrons,knowing they can trust the quality of the products in their hands.

the Way Forward

As we draw the curtains on our exploration of the intricate process behind crafting pre-rolls at dispensaries, it’s clear that this art form marries tradition with modern innovation. From the careful selection of high-quality strains to the precision of each hand-rolled creation, every step is a testament to the dedication and expertise of those behind the counter.The ritual of rolling, once a personal affair, is now transformed into a consumer-friendly experience, making premium cannabis accessible to new and seasoned enthusiasts alike.

In every puff, there’s a story-a narrative woven from the cultivators’ hands to the artisans in the dispensary, and ultimately, to the users who savor the final product. As the industry continues to evolve, the craft of creating pre-rolls stands as a fascinating reflection of a culture that values both artistry and community. Whether you’re lighting up for relaxation, creativity, or connection, the journey of your pre-roll illuminates the passion and skill that go into every meticulously crafted joint.

So, the next time you indulge in a pre-roll, take a moment to appreciate the dedication and craftsmanship behind it.After all, each roll contains not just cannabis, but the spirit of those who brought it to life.