Like a pale, crystalline tide rolling in at low light, THCA has quietly become a focal point for makers, retailers, and curious consumers navigating the evolving world of cannabinoids. Bought in bulk, this raw compound promises efficiency and scale for formulators and enthusiasts alike – but the landscape is layered with legal nuance, quality variation, and choices that can make or break a purchase.

This article takes a steady, practical look at bulk THCA: what it is indeed in plain terms, how legal frameworks shape what products are available, and which markers separate reputable suppliers from risky ones. You’ll find clear criteria for vetting products (think certificates of analysis, purity standards, and supplier clarity), plus smart buying tips to protect your budget and compliance standing. Whether you’re sourcing for a small business,formulating at home,or simply researching,this review aims to map the terrain so you can make informed,responsible decisions.

Legal roadmap for bulk THCA purchases: compliance essentials every buyer should verify

Regulatory lines are rarely straight,and the bulk market for THCA is a textbook example: federal,state and municipal rules intersect in ways that change who can sell,ship and store. Before signing a contract, confirm the product’s legal classification under current hemp statutes and whether it’s dry-weight Δ9‑THC sits comfortably under the statutory ceiling. Also verify transport allowances - what’s lawful to move inside one state may be restricted across state borders.Never assume that past approvals carry forward; documentation must be current.

A practical diligence stack starts with paperwork you can inspect immediately. Ask for and review:

- Certificate of Analysis (COA): third‑party lab results tied to batch numbers and sample dates;

- Seller credentials: business licenses, hemp processor permits, and writen compliance statements;

- Quality standards: GMP, ISO or internal QA protocols and traceability records.

These items prove provenance and let you cross-check potency, contaminants and chain of custody without relying on marketing claims.

Focus your verification on safety thresholds and labeling accuracy. insist that COAs report pesticides, heavy metals, microbial contamination and residual solvents, and that the testing lab is ISO/IEC 17025‑accredited or equivalently reputable. The quick reference table below shows baseline checkpoints many compliance teams use when screening lots:

| Checkpoint | Baseline Expectation |

|---|---|

| Δ9‑THC (dry weight) | < 0.3% |

| Pesticides | ND or below state limits |

| Heavy metals | Below health‑based thresholds |

| Lab accreditation | ISO/IEC 17025 preferred |

bake compliance into your contracts and logistics. require seller warranties, recall procedures, insurance proof and indemnity clauses; define acceptable storage, temperature control and labeling standards; and confirm age‑verification plans for downstream buyers if applicable.Keep a short checklist for each lot you accept-proof of COA, seller license, transportation documentation and a signed compliance addendum-so every incoming shipment maps to an auditable file. Strong paperwork today prevents legal headaches tommorow.

Product types and formulations explained to align inventory with customer needs

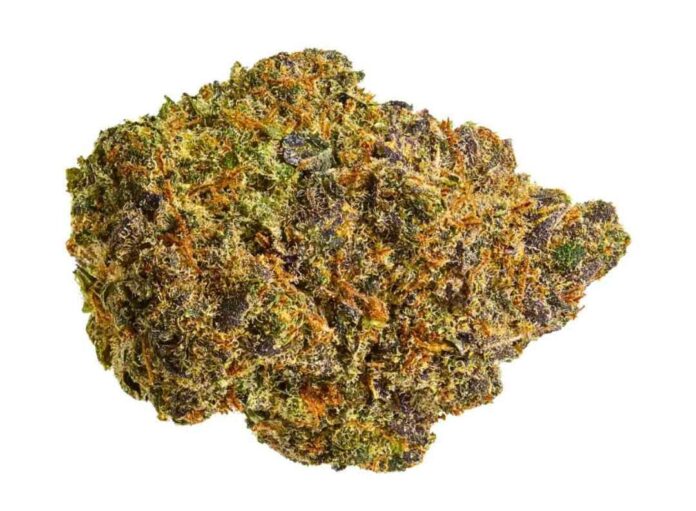

Think of THCA products as ingredients on a shelf – each formulation carries a different texture, potency canvas, and customer expectation. High-purity crystalline (ofen called “diamonds”) offers the cleanest potency spike and is a favorite for manufacturers and labs who need predictable dosing and easy blending. Distillates provide viscous versatility for vape carts and edibles, while isolates sell where ultra-purity and neutral flavor are priorities. Full-spectrum concentrates retain terpenes for aroma-forward applications, and ready-to-sell forms like tinctures, gummies, and pre-rolls satisfy end-users who want convenience over customization.

To match inventory to demand, map formulations to real buyer needs: processors want bulk, boutique shops want finished formats, and health-conscious shoppers may prefer measured tinctures.Offer small-run pilot packs alongside pallet quantities so retailers can test consumer response before committing. keep product samples and clear spec sheets on-hand – frank transparency about purity, solvent residuals, and terpene profiles builds trust and reduces returns.

- Manufacturers: Crystalline, distillate – for predictable dosing and formulation control.

- Retailers: Tinctures, gummies, pre-rolls – ready-to-sell, labeled, and portioned.

- lab/Wholesalers: Isolate and bulk concentrates – ideal for further refinement or custom blends.

Practical logistics matter: some forms need cold storage to preserve terpene integrity,others are shelf-stable for months. Labeling requirements and batch traceability should guide how you package – kilo drums for processors, child-resistant retail packs for storefronts. Below is a quick reference to help decide what to stock next.

| Formulation | Typical Potency | Best Use |

|---|---|---|

| Crystalline | ~95-99% THCA | Concentrates, precision dosing |

| Distillate | 70-90% THCA equiv. | Vape cartridges, edibles |

| Isolate | ~99% pure | Neutral ingredient, custom blends |

| tincture/Gummies | Variable | Retail-ready, measured servings |

reading lab reports like a pro: potency profiles,cannabinoid breakdown and contamination checks

Potency numbers are more than marketing – they’re a recipe. When a COA lists THCA at 80% and Δ9‑THC at 0.2%, don’t just read the headline: convert for reality. labs report cannabinoids as % w/w or mg/g; to estimate the psychoactive potential after decarboxylation, use the conversion factor (THCA × 0.877) + Δ9‑THC = Total THC.Check the date, batch number and lab accreditation on the report, and confirm limits of quantitation (LOQ) so tiny traces aren’t misread as meaningful potency. A chromatogram graphic that accompanies the results is a useful map – it shows clean peaks versus messy baselines that hint at impurities.

Look beyond the star player. The cannabinoid breakdown (CBD, CBG, CBN, CBC and others) sketches the product’s entourage potential and stability: rising CBN can signal age and degradation, while trace CBG or CBC might indicate a more complex profile. Terpene listings (myrcene, limonene, pinene) give clues to aroma and expected effects; they’re measured in mg/g and should complement, not contradict, the cannabinoid totals. If the COA reports “total cannabinoids” that add to far less or more than expected, ask for the raw chromatogram - sometimes overlapping peaks or reporting errors skew the totals.

contamination checks are the safety gate. Heavy metals (lead,arsenic,cadmium,mercury),residual solvents,pesticides and microbial assays (E. coli, Salmonella, total yeast/mold) each have clear pass/fail thresholds in reputable labs. Pay special attention to residual solvent names and their concentrations - solvents like butane and hexane are common in extraction but must sit below regulatory limits. If any analyte is listed as ”Detected, below LOQ” that’s different from “Reported – exceeds action limit” – the latter is a red flag. Certified labs will include method references (GC‑MS, HPLC) and frequently enough a signature or QR code linking back to the full report.

Keep a quick checklist handy and know what good looks like:

- Verify lab accreditation, date, and batch ID.

- Convert THCA to Total THC for true potency estimates.

- Confirm full cannabinoid + terpene lists and request chromatograms if numbers seem off.

- Require clean results for heavy metals, solvents, pesticides and microbes – anything over limits = return or reject.

| Analyte | Typical Range | Action Threshold |

|---|---|---|

| Total THC (post‑decarb) | 0.5% - 85% | Varies by jurisdiction |

| THCA | 0.2% – 80% | Check labeling consistency |

| Lead (Pb) | ND - 0.1 ppm | 0.5 ppm |

| Residual Solvents | ND – trace mg/kg | Regulatory limits (SOLVENT‑SPECIFIC) |

Supplier due diligence and supply chain transparency for reliable bulk sourcing

When buying THCA in bulk, the chain behind the product matters as much as the price. Rigorously checking a supplier’s background – from farm practices to the lab that issues the final Certificate of Analysis (COA) – reduces surprises. ask for recent COAs, request manufacturing process outlines, and verify any claimed certifications. Suppliers that welcome third‑party audits and share batch-level traceability are the ones that stand up under scrutiny.

build a short, repeatable checklist to evaluate new partners. Focus on measurable proof rather than marketing language: test results with cannabinoid profiles and contaminant screens, documented storage and transport conditions, and clear recall procedures. Clear suppliers will provide chain-of-custody documents and be open about who performs their testing and where it occurs.

- COA verification: Confirm the COA matches the batch and comes from an accredited lab.

- Supply chain mapping: Get a clear view of growers, processors, and testing labs.

- Quality management: Look for GMP, HACCP, or ISO alignment, plus routine internal audits.

- Contingency planning: Ensure the supplier has backups for crop loss, testing failures, or shipping delays.

| Document | What it proves |

|---|---|

| Certificate of Analysis (COA) | batch potency and contaminants |

| Chain-of-custody | Traceability from harvest to shipment |

| GMP / ISO statements | Quality management and consistent processes |

Quality signals to prioritize: certificates, batch stability and shelf life

Think of paperwork as the product’s biography – the right documents tell you where it came from and how honest the maker was about what’s inside. Prioritize products that ship with a current Certificate of Analysis (COA) from a reputable lab, and look for manufacturing standards like GMP or ISO identifiers. The COA should show cannabinoid potency, solvents, heavy metals and mycotoxins; if any of those results are missing or vague, treat the item with caution. A quick checklist to keep bookmarked while shopping:

- COA date and lab accreditation (no older than a few months)

- Clear batch number that matches what’s on the package

- Contaminant screens for solvents, pesticides, and microbes

- Claims verification – terpene and potency claims should align with the COA

Consistency is what separates a one-off surprise from a dependable supply.Check for documentation of retain samples and visible batch codes on every container – those allow a lab or supplier to trace odd results back to a specific run. Below is a short stability snapshot to compare typical acceptance thresholds between batches:

| Parameter | Acceptable Variation | Why it matters |

|---|---|---|

| THCA potency | ±10% | Ensures predictable effects |

| Moisture | <1.5% absolute | Prevents mold and degradation |

| Impurities | Non-detect to trace | Safety and regulatory compliance |

Shelf life is not a single number - it’s a relationship between chemistry, packaging and storage. THCA degrades under heat, light and oxygen, so an advertised shelf life is only meaningful if the product was packed in opaque, airtight containers and stored cool. For longer-term buys, favor suppliers who provide recommended storage instructions, batch-specific expiry dates and who offer stability testing data. Simple best practices: keep sealed, store away from heat, and rotate older stock first – these small habits preserve potency and protect your investment.

Smart buying and storage tactics to protect potency, safety and profit

When buying bulk THCA, think like a long-term caretaker rather than a bargain hunter. Prioritize vendors who provide current, unambiguous Certificates of Analysis (COAs), transparent sourcing, and a tested sample policy – then buy a small test batch before committing to pallet-sized orders. Smart buyers balance unit cost with variability risk: sometimes paying a few cents more per gram for consistent potency and clean COAs preserves margins by avoiding expensive remediation, returns, or legal headaches down the line.

- Quick pre-purchase checklist: COA date and lab accreditation, sample shipping window, shelf-life estimate, and freight temperature controls.

- Negotiate staggered deliveries and price breaks tied to quality metrics, not just volume.

- Require lot-level traceability and an agreed-upon quarantine/testing window on arrival.

Storage is chemistry in motion – control the environment and you protect potency and profit. Aim for cool, dark, low-humidity storage: vacuum-sealed containers with inert gas blankets and food-grade desiccants extend stability. Keep stock in clearly labeled, lot-numbered containers and isolate newly received material until third-party verification arrives. simple physical upgrades – insulated shipping,light-blocking drums,and temperature loggers – are often cheaper than repurchasing degraded inventory.

| Condition | Target | Why it matters |

|---|---|---|

| Temperature | 2-8°C (refrigerated) | Slows degradation and decarboxylation |

| Relative Humidity | <40% | Prevents clumping and microbial risk |

| Light Exposure | minimal / opaque packaging | Reduces photodegradation |

operational practices lock in profits: implement FIFO inventory rotation, maintain digital lot records, and retest retained samples periodically. Build relationships with a trusted analytical lab and include pass/fail thresholds in supplier agreements. Lastly, treat compliance as insurance – up-to-date documentation and proactive quality checks turn a potential liability into a competitive advantage, keeping both potency and profit predictable.

In Summary

As you wrap up your search for bulk THCA,remember that the cheapest price tag doesn’t replace careful vetting. Treat each supplier like a delicate experiment: demand up-to-date COAs, verify legal status in your jurisdiction, and balance potency with purity and storage needs. Buying in bulk can unlock savings and consistency, but only when paired with smart due diligence-reputable lab results, transparent sourcing, clear labeling, and sensible dosing guidelines. Keep records,ask questions,and if uncertainty remains,consult a legal or medical professional. With the right checks in place,you can assemble a supply that’s compliant,reliable,and fit for your intended use.