In the realm of natural substances, resin and rosin hold a unique place, each embodying distinct qualities and applications. Though they share a familial bond, often cultivated from the sap of trees, their differences give rise to an intriguing discussion-one that balances the tension between versatility and strength. As artists, craftsmen, and chemists navigate the diverse landscapes of these organic materials, understanding the comparative strengths of resin and rosin becomes crucial. This article delves into their origins, compositions, and mechanical properties, ultimately unveiling how they measure up against one another in various uses. Whether you’re looking to create a durable art piece,a reliable adhesive,or an innovative tool,join us as we explore the intricate dance between resin and rosin,shedding light on which material may reign supreme in different contexts.

Understanding the Basics of Resin and Rosin

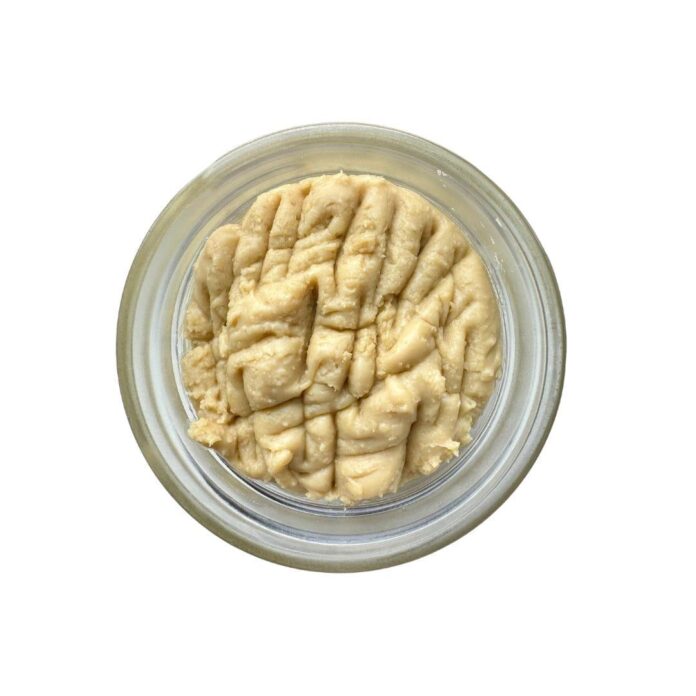

To fully grasp the differences between resin and rosin, it is crucial to start with their definitions. Resin is a viscous organic substance that is secreted by various plants, particularly coniferous trees. It can be either natural or synthetically produced and is known for its strong adhesive properties, durability, and versatility in various applications, including coatings, adhesives, and art supplies. In contrast, rosin, a solid form of resin, is obtained by heating resin to evaporate the volatile components, leaving behind a brittle, amber-like substance. Rosin is predominantly used in the production of inks,varnishes,and as a grip enhancer for musicians,particularly string instrument players.

The composition of these substances plays a notable role in their applications and properties. Resin, typically composed of a mix of terpenes and other organic compounds, exhibits various characteristics based on the source plant and the extraction process. The intricate blend found in natural resins contributes to its effectiveness in creating strong bonds and protective layers. Rosin, though, is primarily made of resin acids, which give it a unique set of properties that make it suitable for specific uses.This simplification of structure allows for easier manipulation, but can also lead to limitations in its performance compared to its parent resin.

| Property | resin | Rosin |

|---|---|---|

| Composition | Complex mixture of terpenes | Primarily resin acids |

| State | Liquid or semi-liquid | Solid |

| Applications | Coatings, adhesives, art supplies | inks, varnishes, musician grips |

| Heat Sensitivity | Sensitive to temperature changes | Stability at higher temperatures |

understanding the fundamentals of resin and rosin also requires a look into their functional properties. Resin’s ability to cure and bond makes it a favorite among artisans and manufacturers looking for materials that enhance durability and mechanical strength. In contrast, rosin’s tackiness and lightweight properties make it beneficial in scenarios requiring temporary adhesion or increased traction, such as on bows used by musicians. This characteristic distinction underlines the importance of selecting the appropriate material for varying projects, whether one is looking for a robust adhesive or a lightweight grip enhancer.

Mechanical Properties and Their Impact on Strength

The comparison between resin and rosin not only hinges on their applications but also significantly depends on their mechanical properties, which ultimately dictate their strength and durability in various environments. Understanding these properties is crucial when selecting a material for specific applications, particularly in fields such as electronics, adhesives, and coatings.

Resin is often synthesized and can be tailored to exhibit high tensile strength, excellent thermal stability, and resistance to various environmental factors. Its mechanical properties generally include:

- High tensile strength: allows for greater load-bearing capabilities.

- Flexibility: Can endure stress without cracking or breaking.

- Low permeability: Reduces the risk of chemical intrusion and degradation.

in contrast, rosin, a natural resin derived from pine trees, offers different mechanical characteristics. While it may not match the synthetic resin’s strength, it holds its own advantages, particularly in certain applications:

- Natural adhesive properties: ideal for applications requiring a sticky surface.

- Brittleness: While it can be strong, it is also more prone to cracking under stress.

- Eco-friendliness: Being a natural product,it reduces environmental impact.

When assessing strength comparison, it is important to note how these mechanical properties contribute to overall performance in real-world applications. for instance, in protective coatings, where flexibility and adhesion are crucial, rosin might excel due to its natural adhesive characteristics, whereas resin could be favored for structural components needing robust tensile strength. The choice between the two therefore lies in the specific demands of the intended request.

| Property | Resin | Rosin |

|---|---|---|

| Tensile Strength | High | Moderate |

| Flexibility | High | Low |

| Impact Resistance | Excellent | Fair |

| Adhesive Quality | Good | Very Good |

Chemical Composition: What Sets Resin Apart from Rosin

Understanding the differences in chemical composition is crucial for appreciating the unique properties of resin and rosin. Both substances originate from plant sources but undergo distinct processes that give rise to their unique characteristics.Resin is an organic compound derived from various trees and plants, known for its complex mixture of terpenes, acids, and volatile compounds.This intricate blend contributes to resin’s versatile applications, including its use in adhesives, varnishes, and even as a natural preservative.

In contrast, rosin is a solid form of resin extracted from pine trees and other plants. Its composition is primarily made up of abietic acid, along with other diterpenes. The extraction process frequently enough involves boiling down the resin, which removes volatile components, resulting in a substance that is less complex than resin. Though it lacks the extensive range of terpenes found in resin, rosin offers its own benefits, such as providing a tacky texture that is favored in applications like musical instrument rosin and in flux for soldering.

| Property | Resin | Rosin |

|---|---|---|

| Source | Various plants | Pine trees |

| Main Component | Complex mixture of terpenes, acids | Abietic acid, diterpenes |

| Uses | Adhesives, varnishes, natural preservative | Musical instruments, soldering flux |

The strength and utility of each substance largely hinge on their composition. Thanks to the diverse array of chemical constituents in resin, it frequently enough exhibits superior flexibility and durability. In comparison, rosin’s composition, while less intricate, allows it to provide efficiency in specific applications, though it may lack the resilience associated with resin.Ultimately, the choice between the two should depend on the specific needs and intended use of the product.

Applications and Performance in real-World Scenarios

In the realm of material science, the choice between resin and rosin is often dictated by the specific requirements of an application. Each material possesses unique properties that can greatly influence performance in various scenarios. For instance,resin,with its superior adhesive qualities and chemical resistance,is frequently utilized in high-stress environments such as aerospace components and automotive parts. The ability of resin to withstand harsh chemicals makes it ideal for protective coatings and seals. In contrast, rosin, derived from natural sources, excels in applications requiring flexibility and natural adhesion, such as in the production of musical instrument strings and various artistic mediums.

When evaluating performance, it is essential to consider factors such as temperature resilience, tensile strength, and curing time. Resin generally offers higher tensile strength, making it suitable for load-bearing applications. The table below illustrates a comparison of key performance metrics:

| property | Resin | Rosin |

|---|---|---|

| Temperature Resilience | High | Moderate |

| Tensile Strength | Exceptional | Good |

| Curing Time | Long | Short |

In real-world applications, the impact of these factors cannot be overstated. Take the construction of composite materials, for example; a combination of resin and fiberglass yields products with astounding durability and lightweight characteristics, perfect for modern aircraft and sporting goods. Alternatively, in the realm of handmade crafts, the flexibility offered by rosin plays a pivotal role, as materials must bend and adapt without breaking, such as in intricate art pieces or specialty furniture. Both materials cater to distinct needs, creating a balanced landscape of applications across industries.

Additionally, the environmental considerations surrounding these materials are gaining momentum. As consumers lean towards sustainability,the advantages of rosin are becoming more pronounced due to its natural origins and lower environmental impact in production. Resin manufacturers are also adapting by developing bio-resins, which aim to combine the performance benefits of traditional resins with a smaller carbon footprint. Choosing the right material isn’t merely a question of performance; it also involves an understanding of the long-term implications and suitability for each application’s unique demands.

Durability and Resistance: Comparing Long-Term Strength

When evaluating the long-term strength of resin and rosin, various factors come into play that highlight their respective durability and resistance properties. Both materials have their unique characteristics, making them suitable for a range of applications, but they often exhibit notable differences when subjected to prolonged stress and environmental exposure.

Resin is generally renowned for its high tensile strength and ability to withstand extreme conditions.It can resist impacts and loads without significant deformation, making it ideal for structural applications. The following points illustrate some of its advantages:

- Water Resistance: Resins are often impermeable, preventing water absorption that could weaken the material over time.

- UV Stability: Many resins are engineered to resist degradation from sunlight, maintaining their clarity and physical properties.

- Heat Resistance: Certain resin formulations remain stable at high temperatures, expanding their usability in various environments.

In contrast, rosin, a natural resin derived from pine trees, exhibits different attributes that make it appealing for specific uses. While it may not match resin in terms of tensile strength,its unique properties lend to a different kind of durability:

- Biodegradability: Rosin is more eco-friendly,breaking down naturally,which is advantageous for applications where environmental impact is a concern.

- Adhesion Strength: Rosin frequently enough provides strong adhesion qualities, making it suitable for use in various adhesive and sealing applications.

- Flexibility: It can offer better flexibility under certain conditions, reducing the risk of cracking.

A comparative analysis of the two materials reveals some interesting insights into their long-term strength. The table below outlines key factors that contribute to their durability and resistance:

| Property | Resin | Rosin |

|---|---|---|

| tensile Strength | High | Moderate |

| Water Resistance | Excellent | Good |

| UV Stability | High | Moderate |

| Heat Resistance | Outstanding | Limited |

| Biodegradability | No | Yes |

while resin generally offers superior durability and resistance, rosin provides advantages in specific applications, particularly in eco-conscious projects or where flexibility and adhesion are prioritized. Understanding these distinctions can definitely help consumers and manufacturers make informed decisions depending on their unique needs and the environments in which these materials will be used.

Choosing the Right Material for Your Project Needs

When embarking on a project, selecting the appropriate material is essential to achieving the desired functionality, durability, and aesthetic appeal. Resin and rosin are two popular choices, each offering unique properties that cater to different applications. Understanding the essential differences between these materials can significantly influence the outcome of your project.

Resin, a synthetic polymer, is known for its versatility and strength. It can be molded into intricate shapes and forms, making it ideal for artistic creations and functional items alike. The properties of resin can be enhanced with additives, allowing for a variety of finishes and functionalities. Some key features include:

- high durability: Resistant to wear and tear.

- Water resistance: Suitable for outdoor applications.

- Flexibility in customization: Available in multiple formulations for specific needs.

In contrast, rosin is a natural resin obtained from pine trees and other plants. It is less versatile than its synthetic counterpart but is appreciated for its eco-friendly properties and unique characteristics. Commonly used in woodworking, music, and as a natural adhesive, rosin also has specific advantages:

- Biodegradable: An environmentally friendly choice.

- Good grip and friction properties: Ideal for various applications like bowing instruments.

- Non-toxic: Safe for use in artistic and educational projects.

| Property | Resin | Rosin |

|---|---|---|

| Source | Synthetic | Natural |

| Durability | High | Moderate |

| Customization | High | Low |

| Environmental Impact | Varies | Low |

the material you choose should align with the specific requirements of your project. If you need something with high durability and customization,resin could be the ideal choice. However, if environmental friendliness and natural properties are at the forefront of your priorities, rosin might be the way to go. Assess your project needs carefully to make the right decision.

To Conclude

as we draw the curtain on this exploration of ”Resin vs. rosin: A Comparative Strength Analysis,” it becomes clear that both materials possess unique qualities that cater to different applications and preferences. While resin boasts a remarkable strength and versatility suitable for various industrial and artistic endeavors, rosin claims its territory with its natural origins and ease of use, making it a favorite among musicians and crafters alike.

the choice between resin and rosin hinges on individual needs, whether you’re seeking the unyielding strength of a synthetic compound or the organic charm of a traditional substance.each material offers its distinctive benefits, ultimately enriching our creative and practical pursuits. So, whether you decide to harness the power of resin or embrace the simplicity of rosin, may your projects be strengthened by the insights shared in this comparative analysis. Happy crafting!