In the ever-evolving world of cannabis consumption, two notable contenders have emerged in the arena of concentrates: shatter and rosin. Both revered for their potency and unique characteristics, thes extracts have sparked a debate among enthusiasts and connoisseurs alike. As the market expands and the understanding of cannabis deepens, consumers are faced with the challenge of choosing between these two popular forms. Is it the glass-like, brittle texture of shatter that holds the allure, or the solventless, artisanal approach of rosin that captures the inventiveness? In this article, we delve into the nuances of shatter and rosin, unraveling their origins, production methods, and the factors that may lead you to prefer one over the other. Join us as we navigate the great extract debate and provide clarity in a landscape that can often feel overwhelming.

The Essence of Extraction Understanding Shatter and Rosin

The world of cannabis concentrates is rich and diverse, with each extraction method boasting its unique characteristics and appeal. Among the various forms of extraction, shatter and rosin stand out not just for their potency but also for their distinctive production processes. While shatter is an extraction that leans heavily on chemistry, using solvents that can yield high THC levels, rosin is celebrated for its purity, relying solely on heat and pressure, making it an appealing choice for those who prioritize a solvent-free experience.

Exploring shatter, one finds that this glass-like concentrate is typically crafted through a solvent-based extraction process, often employing butane or propane to dissolve the cannabinoids and terpenes from the raw plant material. The end result is a product that shatters when handled, so its name.This method not only captures a broad spectrum of cannabinoids but also preserves much of the plant’s original flavor profile. Though, the process does raise questions about safety and residual solvents, which is why ensuring quality control and proper purging is essential.

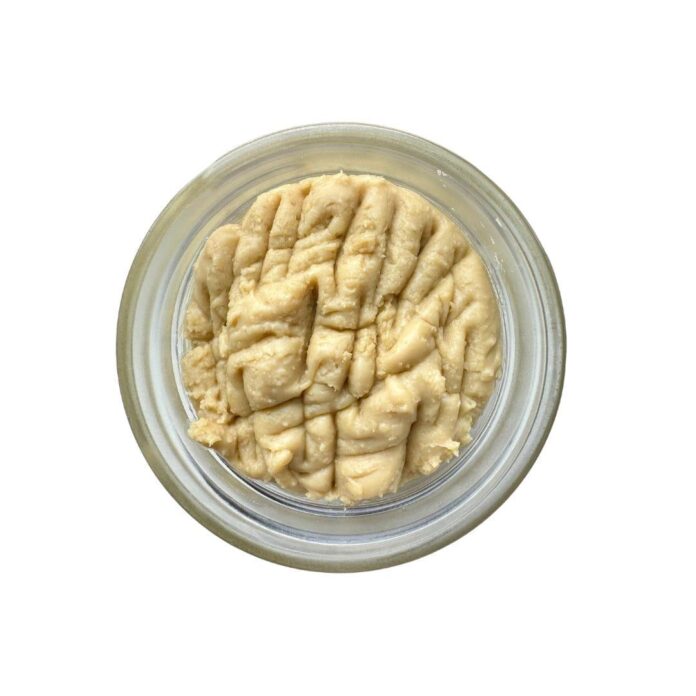

In stark contrast, the rosin extraction method stands as an epitome of simplicity and authenticity.By applying heat and pressure to fresh or dried cannabis flower, rosin is born without the utilization of potentially hazardous solvents. This results in a concentrate that is not only flavorful but also richly aromatic, preserving a bouquet of terpenes that some connoisseurs argue is superior to that found in shatter.With rosin, consumers can indulge in the essence of the plant while minimizing potential health concerns associated with solvent residues.

| Feature | Shatter | Rosin |

|---|---|---|

| Extraction Method | Solvent (Butane/Propane) | Heat & Pressure |

| Consistency | Glass-like, brittle | Gooey or solid, varies |

| Scent & Flavor | Preserved but can differ | Rich and aromatic |

| Health Consideration | Possible solvent residues | solvent-free |

A Closer Look at the Production Process techniques Behind Each Method

Understanding the intricate production processes behind shatter and rosin reveals the unique characteristics that define each method. For shatter, the extraction process utilizes solvents, typically butane or propane. These solvents work to pull cannabinoids and terpenes from the plant material, resulting in a potent and glass-like concentrate. The stages involved can be summarized as follows:

- Extraction: Fresh or dried cannabis is packed into a column.

- Solvent Flow: Butane flows through the column, dissolving the active compounds.

- Evaporation: The mixture is placed under vacuum to evaporate the solvent, leaving behind a concentrate.

- Purging: Residual solvents are removed to ensure safety and potency.

In contrast, the rosin production technique stands out due to its solventless nature. By applying heat and pressure, rosin is extracted directly from the cannabis flower or hash. This method has gained popularity for its ability to preserve the plant’s natural flavor profile and essential oils.The key steps in rosin extraction include:

- Preparation: The starting material is pre-heated to enhance the extraction process.

- Pressing: Using a heat press, pressure is applied, which helps to release the oils.

- Collection: The resulting rosin is scraped off from the parchment paper to be collected.

Ultimately, both extraction methods offer distinct experiences for consumers.shatter, with its high potency and structure, often appeals to those looking for a concentrated form of cannabis while allowing for effective dabbing. On the other hand,rosin’s clean,solvent-free approach attracts those who prioritize a more natural product with rich flavors. Below is a swift comparison of both methods:

| Feature | Shatter | Rosin |

|---|---|---|

| Method | Solvent-based extraction | solventless heat and pressure |

| Flavor | Often more intense | Retains natural flavors |

| Potency | Very high | Moderate to high |

| Safety | Varies, requires purging | Generally safe |

Flavor Profiles unveiling the Taste Differences Between Shatter and Rosin

When it comes to cannabis extracts, both shatter and rosin offer distinct flavor experiences, influenced by their processing methods and the strains used. Shatter, renowned for its glass-like consistency, often boasts a complex flavor profile that can vary considerably based on input materials. Its extraction process, reliant on solvents, allows for a concentration of terpenes and cannabinoids, often resulting in a more intense flavor that appeals to connoisseurs seeking a full-spectrum experience.

On the other hand, rosin is celebrated for its natural approach, deriving its essence from heat and pressure applied to the plant material. This method not only preserves vital terpenes but can also enhance certain flavor notes, offering a more earthy and robust profile. Many users note that rosin can capture the true essence of the strain, providing a cleaner and more authentic taste that resonates with the original flower.

| Characteristic | Shatter | Rosin |

|---|---|---|

| Flavor Intensity | High | Moderate to High |

| Terpene Preservation | Varies | Excellent |

| Processing Method | Solvent-Based | Solventless (Heat & Pressure) |

| Texture | Glass-like | Sticky, Oily |

Ultimately, the choice between shatter and rosin often comes down to individual preference. Enthusiasts may favor shatter for its potent, explosive flavor characteristics while others lean towards rosin for its purity and authenticity. exploring both can lead to a greater gratitude of the diverse offerings within the cannabis extraction landscape, allowing users to tailor their experiences according to their palate and desired effects.

Potency and Purity Comparing the Strength and Quality of Extracts

When delving into the realm of cannabis concentrates, understanding both potency and purity is crucial in making an educated choice between shatter and rosin. Each extract offers its unique advantages, but their profiles may differ significantly based on their production processes and the raw materials used. a balance between strength and quality dictates the consumer’s experience.

Potency is often measured by the cannabinoid concentration, primarily THC or CBD. Shatter, being a butane-extracted product, typically boasts higher THC percentages ranging from 70% to 90%. The appeal of shatter lies in its potential for a more robust high, making it a favorite among seasoned users seeking a powerful experience. conversely, rosin, produced by mechanical pressing, often results in slightly lower potency levels, usually between 50% and 80%. though, many enthusiasts argue that rosin’s potency can still provide an equally satisfying experience due to the premium starting material used in its extraction.

Purity is where the debate takes an engaging turn. Shatter, despite its high potency, may carry traces of residual solvents from the extraction process. For many conscientious consumers, this raises questions about its overall quality and safety.In contrast, rosin extract is frequently enough heralded for its purity as it is indeed solventless, which many consider a significant benefit for those prioritizing a clean and natural product. however,it’s essential to note that the purity of rosin can depend heavily on the quality of the source material used,with flowers and hash being the primary options for extraction.

| Aspect | Shatter | Rosin |

|---|---|---|

| Extraction Method | butane Extraction | Heat and Pressure |

| Typical Potency | 70% – 90% THC | 50% – 80% THC |

| Purity | May contain residual solvents | Solventless, but quality dependent |

| User Preference | strong high seekers | Purity-focused users |

Consumption Methods Exploring Ways to Enjoy Shatter and Rosin

When it comes to indulging in the flavorful world of cannabis concentrates,shatter and rosin offer distinct experiences that can enhance your enjoyment. Here are some popular methods to savor these extracts:

- Dabbing: One of the most popular techniques for consuming both shatter and rosin involves using a dab rig. This method allows users to heat a small amount of the concentrate on a heated nail, producing a potent vapor that showcases the full flavor profile.

- Vaping: For those who prefer a smoother inhalation experience, utilizing a vaporizer designed for concentrates is ideal. Many vaporizers offer adjustable temperature settings,allowing you to customize the flavor and potency of your sessions.

- Topping Flower: Elevate your smoking experience by adding shatter or rosin to your bowl of flower. This method enhances the overall potency and introduces a more complex flavor profile, combining the characteristics of both the flower and the concentrate.

- Infusing Edibles: Both types of extracts can be incorporated into homemade edibles for a unique culinary twist. Melt the concentrate into oils or butters, which can then be used in recipes to create appetizing infused treats with a longer-lasting effect.

for those interested in comparing the characteristics of shatter and rosin, the table below highlights key differences:

| Characteristic | Shatter | rosin |

|---|---|---|

| Method of Extraction | Solvent-based | Solventless (heat and pressure) |

| Texture | Brittle, glass-like | Sticky, gooey |

| Flavor Profile | Strong terpene profile | Natural, often more flavorful |

| Potency | High (up to 80% THC) | High (varies, often 50-70% THC) |

Exploring these consumption methods can take your cannabis experience to new heights. Whether you choose to dab, vape, or infuse these concentrates into your favorite recipes, each method opens the door to unique flavors and effects that highlight the potency of shatter and rosin. So, gather your friends, experiment with different techniques, and discover which methods elevate your enjoyment of these extracts.

Making an Informed Choice Recommendations for Selective Consumers

When it comes to choosing between shatter and rosin, understanding their unique characteristics can empower consumers to make a decision that aligns with their preferences and intended use. Each extract method brings its own set of attributes that cater to different experiences and needs.

Shatter is revered for its high purity and potent effects, often appealing to seasoned cannabis users. Made from the extraction of cannabinoids using solvent techniques, shatter typically presents a glass-like consistency and a vibrant colour. Here are some points to consider:

- Effectiveness: Ideal for high THC concentrations, providing powerful psychoactive effects.

- Flavor: Retains a broad spectrum of terpenes, enhancing flavor profiles.

- Consumption: Best for dabbing and experienced users, requiring specific equipment.

On the other hand, rosin has gained traction among health-conscious consumers and those who prefer a solvent-free option. Created through a heat-and-pressure extraction process, rosin prides itself on being a cleaner and more natural extract. Here’s what to keep in mind:

- Purity: no solvents used, appealing to those seeking a clean consumption method.

- Flavor and Aroma: Frequently enough more robust in flavor,emphasizing the strain’s natural characteristics.

- accessibility: Can be made at home, making it an attractive option for DIY enthusiasts.

Choosing between shatter and rosin ultimately boils down to personal preference. For a side-by-side comparison reflecting crucial differences, refer to the table below:

| Feature | Shatter | Rosin |

|---|---|---|

| Extraction Method | Solvent-based | Heat and pressure |

| Purity Level | High | Very High |

| Flavor Profile | Terpene-rich | Strain-true |

| Consumption Method | Dabbing | Dabbing, Vaporizing |

future Outlook

As we draw the curtains on this exploration of the great extract debate, it becomes clear that both shatter and rosin have carved out their unique places in the world of cannabis. Each method of extraction tells a different story, catering to a diverse array of preferences, palates, and purposes. Whether you’re drawn to the crystalline allure and potency of shatter or the natural purity and artisanal charm of rosin, understanding these distinctions is essential for informed choices in your cannabis journey.

The debate may continue,fueled by personal preferences and evolving techniques,but at the heart of it all lies the shared passion for the plant and the community it fosters. So, as you navigate this vibrant landscape of extracts, remember that the true essence of cannabis lies not just in the products we choose, but in the experiences and connections we forge along the way.Happy exploring!