Title: The Art and Science of THC Resin Production

In the ever-evolving landscape of cannabis, THC resin stands as a remarkable testament to the plant’s versatility and allure.For enthusiasts and novices alike, this potent extract has captured attention for its concentrated effects and vibrant flavor profiles. But what exactly goes into the creation of THC resin? How does the simple act of cultivating cannabis transform into this rich, sticky substance that embodies the essence of the plant? in this article, we delve into the intricate process of making THC resin, exploring the delicate interplay of art and science that brings forth this treasured extract. From the careful selection of strains to the methods of extraction, we will unravel the journey of THC resin, shedding light on the craftsmanship behind each batch and the knowledge that propels this ancient practice into modern innovation. Join us as we embark on a journey through the world of cannabis extraction, illuminating the steps that transform raw plant material into a concentrated masterpiece.

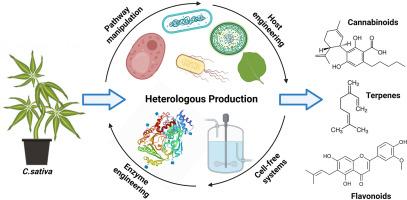

Understanding the Basics of THC Resin Production

THC resin production begins with the careful selection of cannabis strains known for their high tetrahydrocannabinol (THC) content. Cultivators prioritize strains that not only yield potent buds but also produce a rich terpene profile, enhancing the overall quality of the resin. This initial step is crucial as it sets the foundation for the extraction process and defines the characteristics of the final product.Once the plants are mature, they are harvested and dried to prepare for extraction.

There are several common methods for extracting THC resin, each with its unique benefits and intricacies. The most popular methods include:

- solvent Extraction: Utilizing solvents like ethanol or butane to dissolve the cannabinoids from the plant material.

- CO2 Extraction: A sophisticated method that uses pressurized carbon dioxide to extract cannabis oils, ensuring a cleaner, purer product.

- Ice Water Extraction (Bubble Hash): Involving ice water and agitation to separate trichomes from the plant, resulting in a high-quality resin.

Each technique results in different types of concentrates, impacting both potency and flavor.Post-extraction, the resin can undergo decarboxylation to activate its psychoactive properties, enhancing the user experience. Understanding the nuances of these extraction methods is vital for anyone looking to appreciate or produce THC resin effectively.

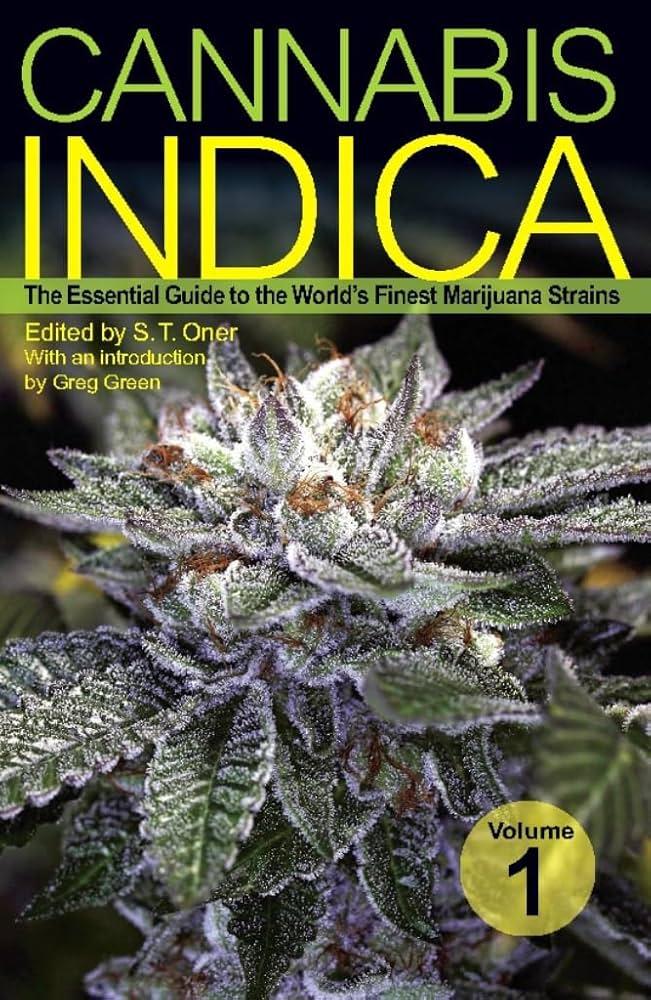

The Role of Cannabis Strains in Resin Quality

The quality of resin extracted from cannabis plants heavily relies on the specific strains utilized during the production process. Each strain possesses a unique genetic profile, leading to distinct terpene and cannabinoid combinations that influence the overall resin characteristics. The careful selection of these strains can enhance or diminish the resin’s flavor, aroma, and potency, making strain choice a critical aspect of resin production.

When cultivating cannabis for resin extraction, growers often prioritize high-resin strains. These strains typically produce ample amounts of trichomes, the tiny, glandular structures responsible for resin production. Some of the notable traits to consider in these strains include:

- THC Content: Higher THC levels usually correlate with a more robust resin yield.

- Terpene Profile: Terpenes contribute to the fragrance and flavor, which reflect in the extracted resin.

- Growth Surroundings: factors such as light,temperature,and humidity can impact resin quality.

Here is a simple comparison of popular cannabis strains known for their resin quality:

| Strain | THC Level (%) | Key Terpene |

|---|---|---|

| Girl Scout Cookies | 18-28 | Caryophyllene |

| Blue Dream | 17-24 | Myrcene |

| OG Kush | 19-26 | Limonene |

understanding the relationship between cannabis strains and resin quality can substantially enhance the resin extraction process. By selecting the right strains according to desired attributes, cultivators can produce superior resin that meets the demands of both recreational and medicinal users, ultimately elevating the experience delivered through the extracted product.

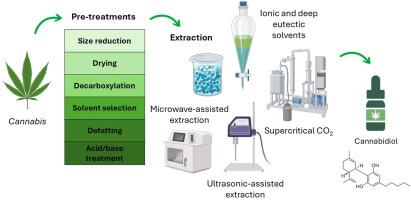

Extraction Techniques: Comparing Methods for Maximum Yield

When it comes to extracting THC resin from cannabis, various techniques are utilized, each offering its own advantages and challenges. Among the most popular methods are solvent-based extractions, mechanical extractions, and CO2 extractions. Solvent-based methods typically involve the use of substances like ethanol, butane, or propane, which dissolve the resinous materials from the plant.The key benefit of solvent extraction lies in its efficiency and ability to produce high yields, but it requires careful handling to avoid residual solvents in the final product.

Mechanical extraction, on the other hand, focuses on physical methods to draw out resin without the need for chemicals. Techniques such as dry sifting or bubble hashing employ ice and water to separate trichomes from the plant material. This method is celebrated for its purity, as it preserves the full spectrum of cannabinoids and terpenes found in the original plant. Tho, it may result in lower yields compared to solvent methods, as it is indeed frequently enough more labor-intensive and requires precise technique.

Lastly, CO2 extraction has gained popularity in recent years for its ability to produce high-quality extracts without using harmful solvents. By manipulating temperature and pressure, CO2 is transformed into a supercritical state that efficiently extracts cannabinoids while leaving behind chlorophyll and other unwanted compounds. Even though this method typically requires a higher initial investment for specialized equipment, the resultant product is frequently enough considered the cleanest and most potent. Below is a table summarizing these extraction methods:

| Extraction Method | Yield Efficiency | Purity | Cost |

|---|---|---|---|

| Solvent-based | high | Variable | Low to Medium |

| Mechanical | Medium | High | medium |

| CO2 Extraction | High | Very High | High |

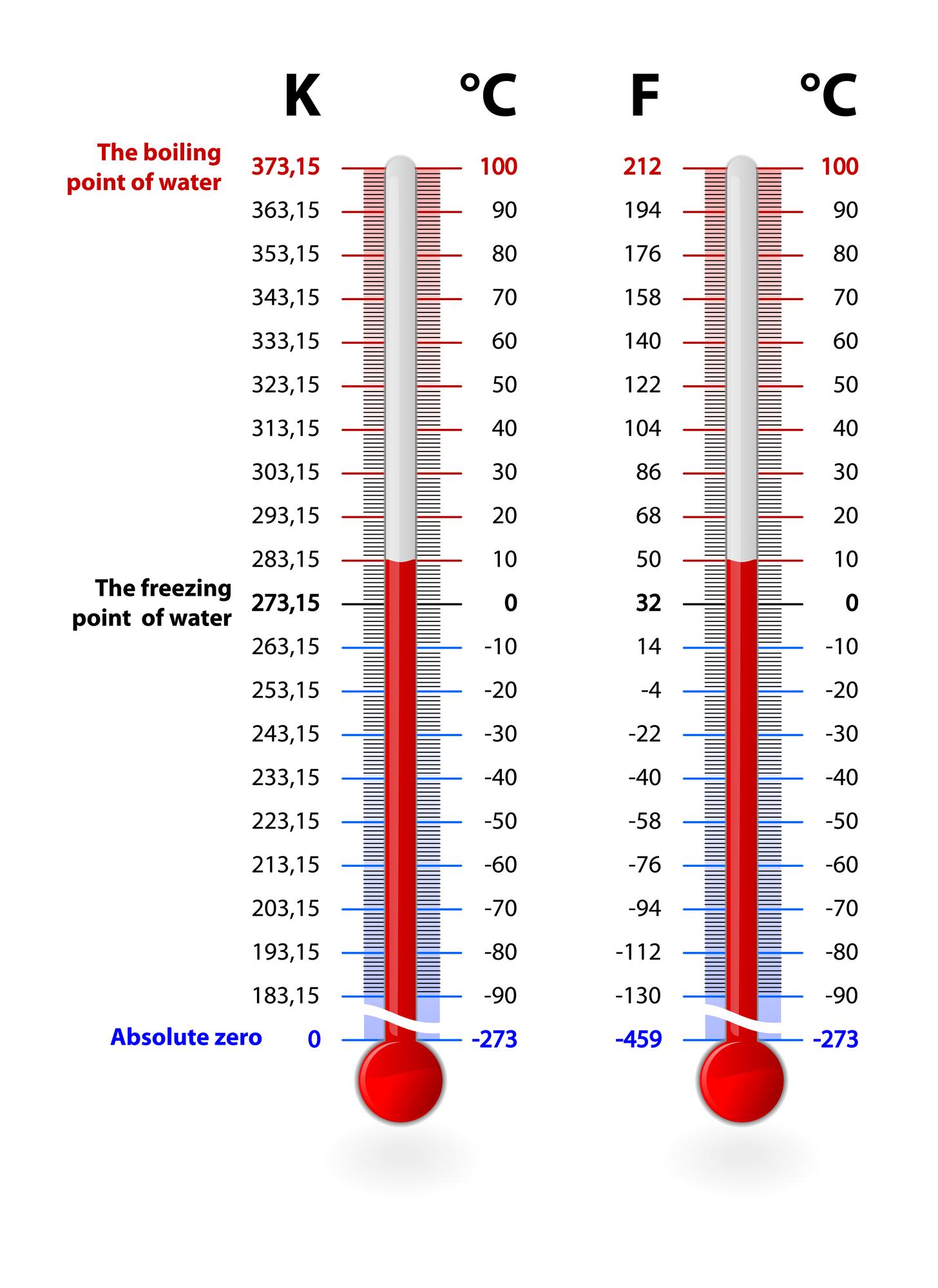

The Importance of Temperature and Timing in Extraction

The process of extracting THC resin hinges critically on the delicate balance of temperature and timing. Each strain of cannabis possesses unique profiles that respond differently to heat during extraction. When the temperature is too low, the activation of cannabinoids like THC can be incomplete, resulting in a less potent final product. Conversely, excessive heat can lead to the degradation of these compounds, diminishing the quality of the resin. Controlled temperature settings ensure that the full spectrum of terpenes and cannabinoids are preserved, creating a more flavorful and effective resin.

timing, on the other hand, plays a pivotal role in the extraction workflow. The process must be precisely calibrated to allow for optimal infusion of flavors and potency. During extraction, the contact time between the cannabis material and the solvent can drastically influence the resin’s characteristics. Shorter extraction times might yield lighter, more aromatic resins, while extended periods can bring out deeper, more robust flavors. It’s vital to monitor these variables to achieve the desired profile:

- Short Extracts: Lighter flavor profiles, less color

- Medium Extracts: Balanced flavor with moderate potency

- Long Extracts: Intensified flavor, darker color

Taking this into account, the following table summarizes recommended temperature ranges and extraction times for different extraction methods:

| Extraction Method | Temperature Range (°F) | Recommended Time |

|---|---|---|

| Cold Extraction | 32-40 | 24-48 hours |

| Warm Extraction | 60-80 | 3-6 hours |

| Hot Extraction | 180-220 | 15-30 minutes |

Ultimately, mastery of temperature and timing can lead to expertly crafted THC resin that balances potency, flavor, and aroma. these factors should be meticulously fine-tuned to achieve the best possible outcome in resin production, contributing to the overall efficacy and enjoyment of the final product.

Post-Extraction: Purification and Refinement Tips

Once the resin is extracted, the next crucial stage is purification to enhance its potency and cleanliness. This process is essential to ensure that the final product is free from impurities and unwanted compounds that could affect its quality. Here are a few strategies for effective purification:

- Filtration: Utilize fine mesh filters or screens to remove plant particles and larger impurities. This step can significantly improve the purity of the resin.

- Solvent Evaporation: For solvent-based extractions, gently evaporating the solvent under controlled conditions helps in reclaiming high-quality resin.

- Cold Water wash: This method entails washing the resin with cold water to further separate unwanted materials, yielding a cleaner product.

Refinement is equally crucial as it determines the final texture and potency of the THC resin.Different methods can be employed to achieve a desired consistency and quality. For example,a common method involves vacuum purging which removes any residual solvents while simultaneously enhancing terpenes’ profile. Additionally, techniques such as decarboxylation can transform THCA into psychoactive THC, improving the effects without compromising safety.

| Extraction Method | Purification Technique |

|---|---|

| Butane Extraction | Vacuum Purging |

| CO2 Extraction | Cold Water Wash |

| Solventless Methods | Hand Pressing |

Ultimately, monitoring the purity and refinement process can vastly improve the quality of your THC resin. Identifying the right combination of purification and refinement techniques tailored to your extraction method can produce a high-grade product. Enhancing the sensory characteristics of the resin through the preservation of terpenes will not only elevate its fragrance and flavor profile but also contribute positively to the overall user experience.

Safety and legal considerations in THC Resin Manufacturing

When engaging in the manufacturing of THC resin, safety is paramount. The process often involves the use of volatile solvents or gases, which can pose serious risks if not handled properly. It is crucial to operate in a well-ventilated area, utilize professional-grade equipment, and wear appropriate personal protective equipment (PPE) including gloves, goggles, and respirators. Additionally, maintaining a clean workspace free from flammable materials greatly reduces the risk of accidents.

Beyond safety precautions, understanding the legal landscape is essential. Laws surrounding the production, possession, and distribution of THC resin can vary significantly between jurisdictions. For example, while some states or countries have legalized cannabis products, others maintain strict prohibitions. Engaging with local regulations helps manufacturers avoid legal complications. Key legal considerations include:

- Licensing requirements

- Testing and quality control standards

- Labeling regulations

It’s also vital to establish a clear understanding of product liability and its implications. Manufacturers should consider implementing rigorous testing protocols to ensure the purity and potency of their product.This not only helps in abiding by local laws but also builds a trustworthy relationship with consumers. A simple table below outlines some general legal considerations in THC resin manufacturing:

| Consideration | Description |

|---|---|

| Licensing | Ensure all necessary permits are obtained before manufacturing. |

| Testing | Conduct regular tests for contaminants and potency. |

| labeling | Follow guidelines for product information and warning labels. |

Insights and Conclusions

the creation of THC resin is a interesting interplay of nature and science, where the raw beauty of cannabis meets the precision of extraction techniques.From the careful cultivation of the cannabis plant to the intricate processes that refine its potent compounds, each step is a testament to both the craftsmanship of growers and the innovations of modern extraction methods. As the understanding and appreciation for THC resin continues to evolve, it opens doors to new possibilities in consumption, creativity, and therapeutic applications. Whether you’re an experienced connoisseur or a curious newcomer, the journey of THC resin invites us all to explore the complexities of this remarkable substance, reminding us of the dynamic relationship between humanity and the natural world. So,as you delve deeper into this realm,may your discoveries be enlightening and your experiences enriching.